The importance of reinforcement

- Home

- Technical

- What are liquid applied membranes

- The importance of reinforcement

- The importance of reinforcement

Navigating the vast array of liquid waterproofing systems available can often prove challenging, sometimes leaving specifiers and contractors perplexed about the most fitting solution for their project. At the LRWA, we have witnessed firsthand the unfortunate outcomes of projects gone awry due to the installation of inappropriate products.

Specifying a liquid-applied membrane with reinforcement must be the default solution when it comes to choosing a system. Although there are exceptions, which will be explained below, reinforcement will minimise the risk of a system failing.

- Avoiding pitfalls

While certain products without reinforcement may promise utopia in a tin with long-lasting durability, it is imperative to verify their suitability for specific substrates. The easiest and most effective way to do this is by checking third-party accreditations such as British Board of Agrément (BBA), European Technical Approvals (ETA) or BDA certificates.

The LRWA has also developed specialist guidance and tools to help specifiers navigate the suitability of liquid roofing products to minimise risks. The Liquid Roofing Finder, for example, is a free online tool which uses third party accreditation to enable specifiers, distributors and contractors to quickly assess the suitability of liquid roofing systems, including the substrates they have been approved for.

- Why reinforcement matters

Over the years, the LRWA has observed some manufacturers introduce liquid systems to the UK market that lack a reinforcement layer. Products mostly sold through merchants, have been seen to tout cost effectiveness and quicker installation as their prime advantages.

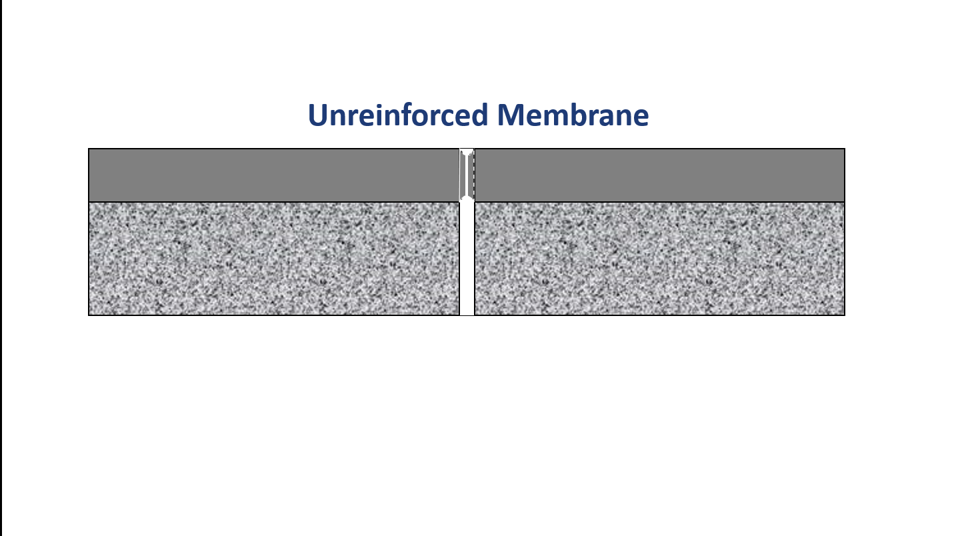

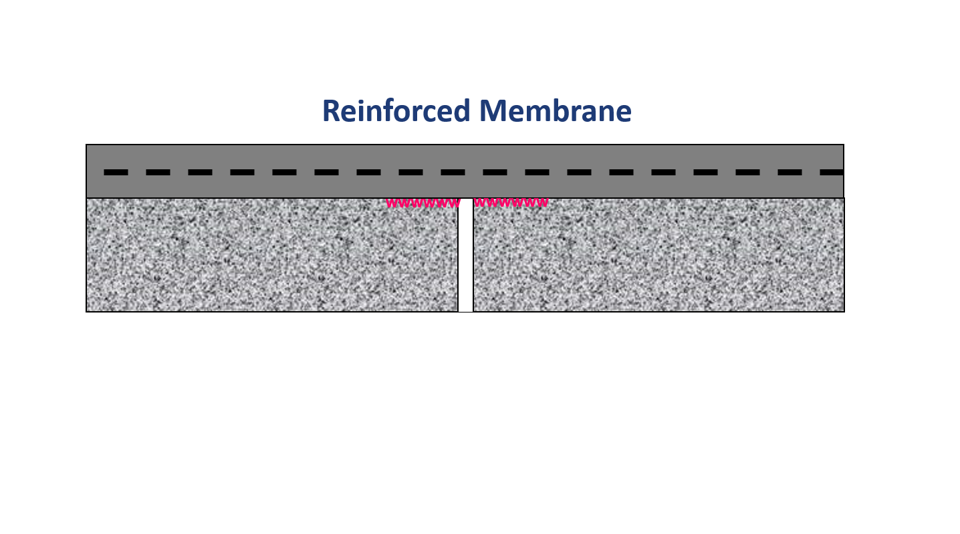

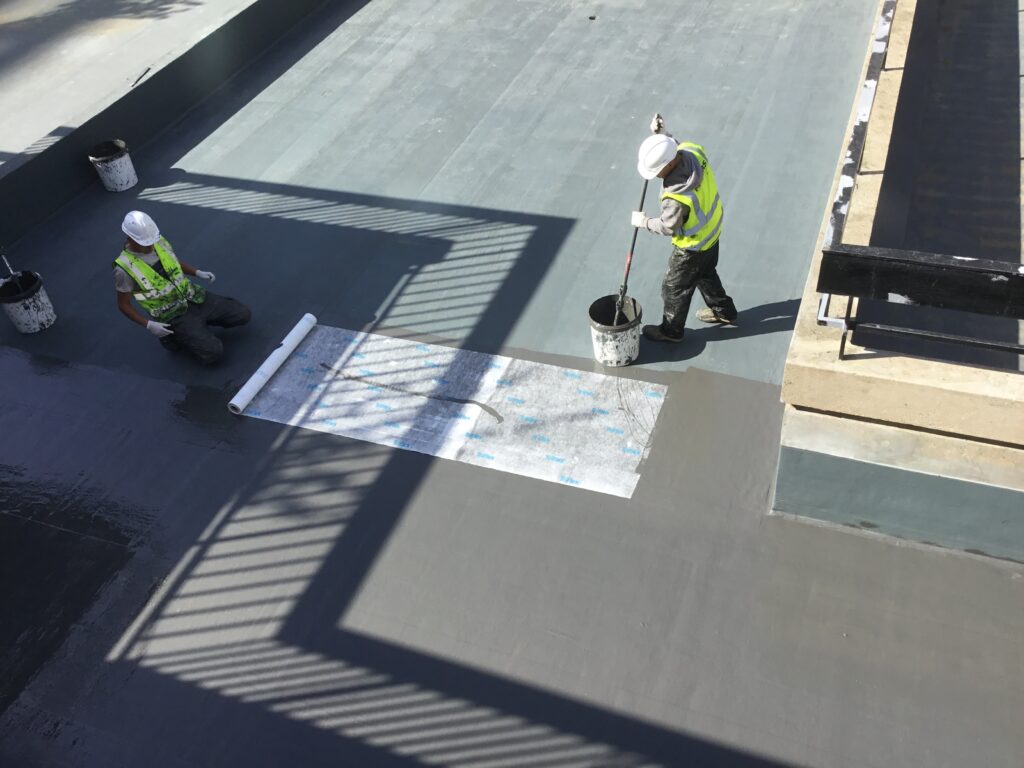

Cold-applied liquid waterproofing, specified predominantly within refurbishment projects, is often overlayed onto existing roofing systems. Reinforcement enhances the tensile strength of the liquid waterproofing, consequently reducing material elasticity. Reinforcement layers typically comprise of materials such as a polyester fleece or glass fibre mat. This facilitates greater thermal or structural movement in the substrate, thereby diminishing stress in the membrane at movement points. Applied correctly, the strength of the reinforcement surpasses the bond to the substrate, allowing for greater movement and eliminating the risk of any damage to the membrane.

Areas of concentrated stress such as upstands, movement cracks, and expansion joints is where the need for reinforcement is most evident.

Reinforcement also facilitates crack bridging, especially if cracks emerge post-application of the liquid-applied membrane within a roof or balcony substrate. A fully reinforced system boasts significantly higher overall strength than liquid resin alone. Consequently, in the event of a crack formation, a reinforced system offers enhanced flexibility on either side of the crack, thereby mitigating potential issues.

- Installation considerations

Installing an unreinforced system could result in heightened stress rather than elongation, potentially jeopardising the system’s longevity and integrity. This risk remains even if a crack wasn’t present during the system’s installation, as no liquid applied resin alone can possess infinite capabilities.

Contractors should be mindful that certain liquid waterproofing systems lacking a reinforcement layer often recommend incorporating reinforcing strips over cracks, joints, or stress points to enhance performance in critical areas. However, this adds to the project’s cost without providing a comprehensive seamless reinforced system.

Reinforcement also ensures consistent thickness of the waterproofing membrane, which is crucial for enduring foot traffic and varying weather conditions in the UK’s diverse climate.

- Exceptions to the rule

There are some instances where specialist liquid-applied waterproofing membranes do not require reinforcement. This is mostly those systems that are extremely fast curing, and typically approved solely for use on concrete which is usually required for new-build applications.

Additionally, liquid-applied membranes used for application on materials like metal profiled or asbestos cement sheets may require partial reinforcement for areas prone to movement. In such cases, specifiers and contractors should consult the manufacturer’s guidelines regarding the substrates tested with partially or non-reinforced systems.

- Useful links

- Members area

- Join LRWA

- Latest events

- Latest vacancies

Listed below are the latest jobs posted by our LRWA members.